buzzard767

golfaknifeaholic

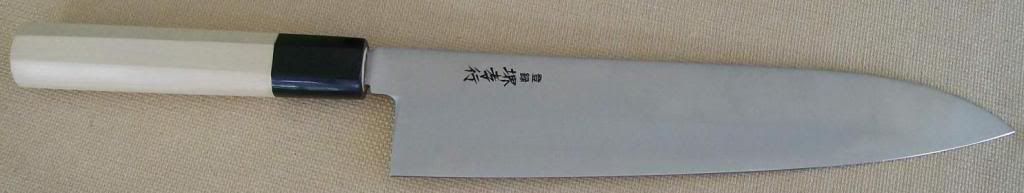

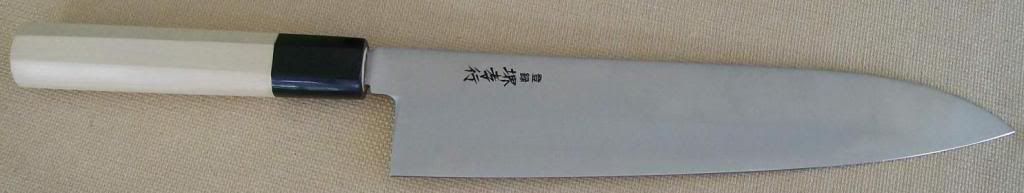

I just received a Sakai Takayuki Grand Cheff 240mm wa Gyuto.

This post is going up on a couple of knife specific sites tomorrow. Those guys know all the slang and shortcuts so I'll be adding additional information for NCT, all in blue. Sakai Takayuki is a Japanese manufacturer with a very wide range of knives, most are high end. The Grand Cheff series is in the middle somewhere. 240mm = 9.4" and that is the length of the cutting edge itself, from the heel to the tip. "wa" indicates a traditional Japanese handle as opposed to our familiar Western style handles. "Gyuto" literally means cow sword in Japanese. The reason I go into the detail I do is because I am the first to have obtained this particular knife. I placed my order 11-6-08 and it just arrived yesterday. The other folks know about it and they're waiting for my report. NCT gets it first.

I only have two other 240 Gyutos at this location for comparison, a 240 Yoshikane SKD and a 240 Aritsugu "A". Neither are very skinny but the pictures will show the relative dimensions. The spine is not eased like the Yoshi but is not nearly as sharp as the Aritsugu.

Edge: Out of the box and examined with a 20x loupe. The bevel apprears to be 50/50 and sharpened to about 2k.

"2k" refers to 2000 grit, the finest stone used by the maker to sharpen this knife.

Measurements are in millimeters.

Length:

Taka 240

Yoshie 248

Arit 236

Height at heel:

Taka 52 - lots of guys like knives a little on the wide side (I think me too)

Yoshi 47.6

Arit 44.5

Spine width above heel:

Taka 2.0

Yoshi 3.5

Arit 2.4

Thickness of blade at the heel half way between the spine and the edge:

Taka 1.0

Yoshie 2.3

Arit 1.4

Flexibility:

Taka Somewhat, but not too much

Yoshie Like a section of railroad track

Arit Slightly stiff as a knife like this should be

Fit and Finish is very nice. I already own a Grand Cheff 150mm Petty and knew what to expect.

"Petty" describes a Japanese kitchen utility knife.

The blade is solid SS AEB-L strip steel at RcH 58.

Swedish Uddeholm AEB-L is the twin sister of Sandvik 13C26. This is the steel from which nearly all safety razor blades are made. It is stainless, which is great for the home where the knife might be left wet on the counter or (shudder) in the sink for extended periods. This steel has very few impurities, and along with its tiny carbides that give it the ability to be made very sharp, is perfect for certain knife uses. "RcH 58" refers to how hard the steel is as measured by the Rockwell C Scale. As reference, German forged knives are in the 52-56 range and Japanese knives are generally 58-64. The scale is non-linear and means that 58 is much harder than 55. S.Sheperd can fully explain it if anyone cares.

I couldn't believe the edge. The bevel was hard to spot without magnification. To measure the angle I used an EdgePro Apex and a magic marker. It was a whopping 24 degrees per side, right up there with Wusthofs and the like. WTF? In its defense, it push cut computer paper quite well at 1/4" from the pinch. Magnified, the bevel widths were the same throughout the length of the blade.

More on push cutting on a follow up post.

Are you still with me? Wait till you see what this knife can do.

Geometry: The next two pictures tell the tale. The spine shot has the Yoshikane on the top and the Aritsugu on the bottom. The choil shot needs no explanation whatsoever.

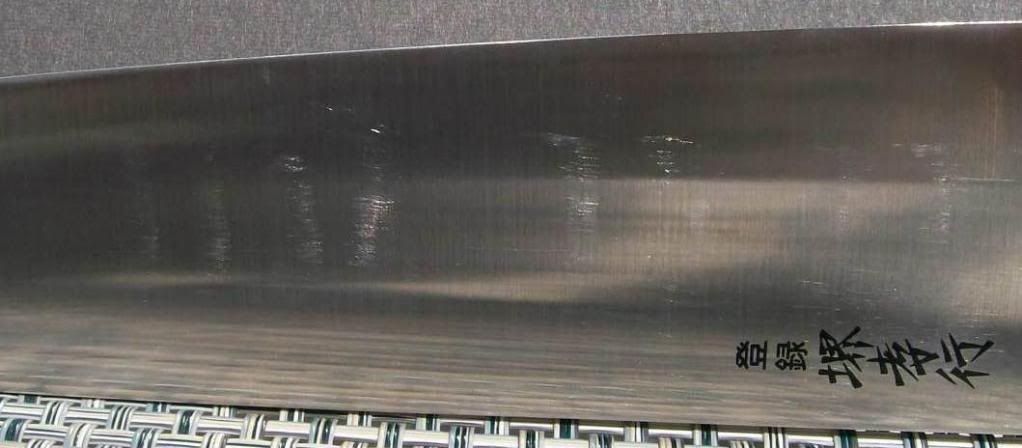

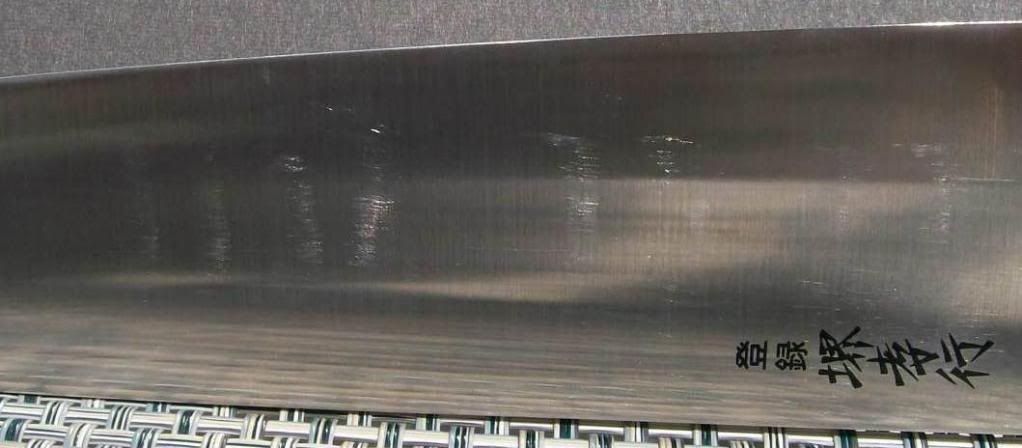

Time to sharpen this sucker. Here's the stock bevel:

I'm a lefty and decided to sharpen the left side only - thank you so much Master KC Ma. LOL

Grit progression was:

Bester 700

Shapton Glass Stone 1k, 2k, 4k, 8k

Naniwa Super Stone 10k

Strop on leather .5 micron Chromium Oxide

Strop on leather .25 micron Hand American Diamond Spray

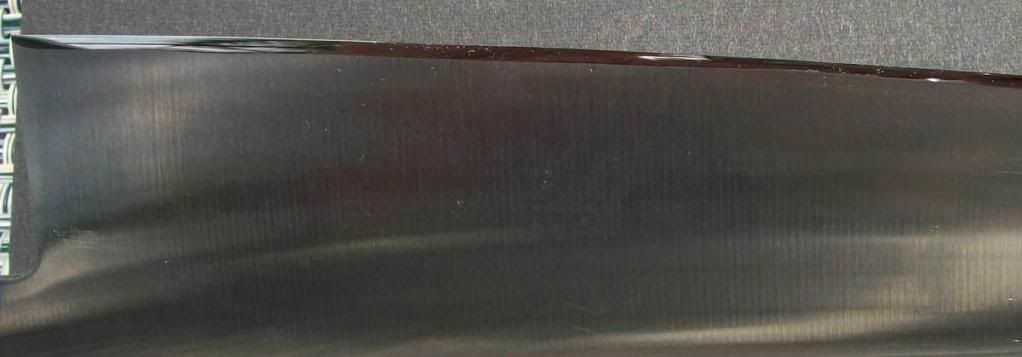

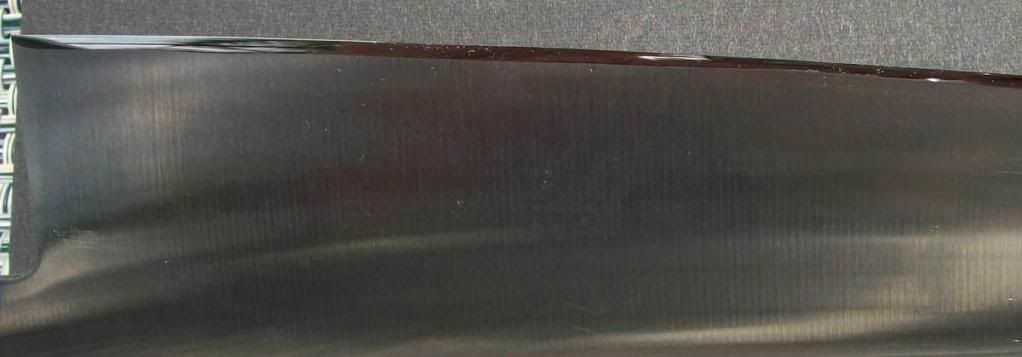

Here's the new left bevel at about 6-7 degrees:

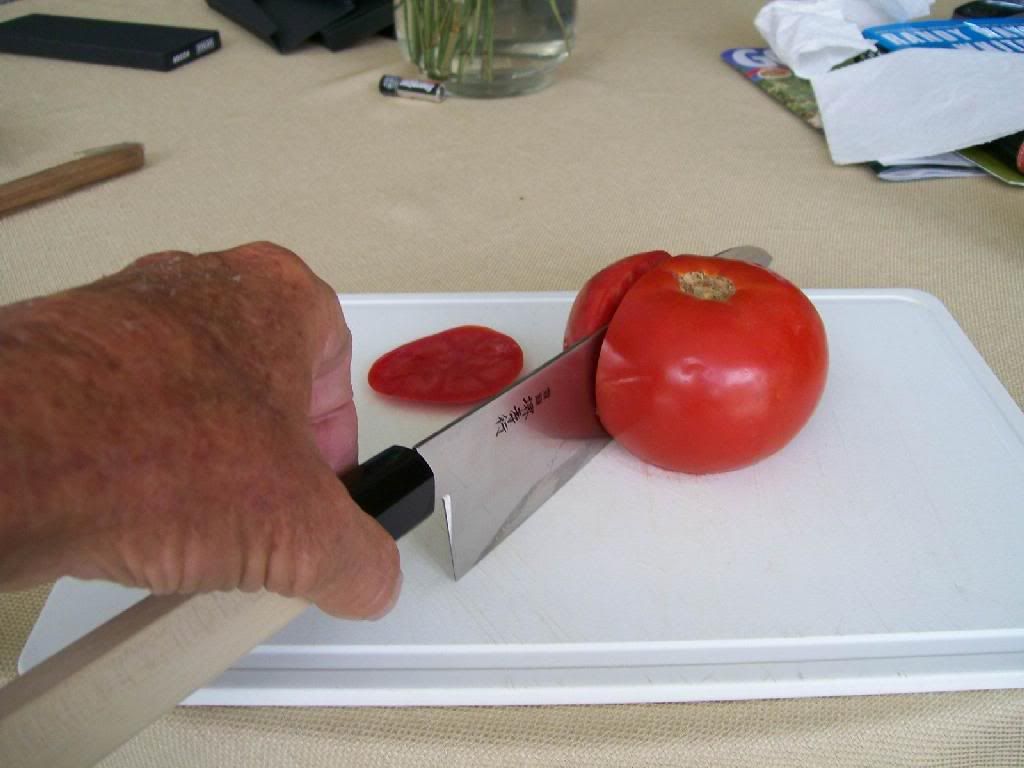

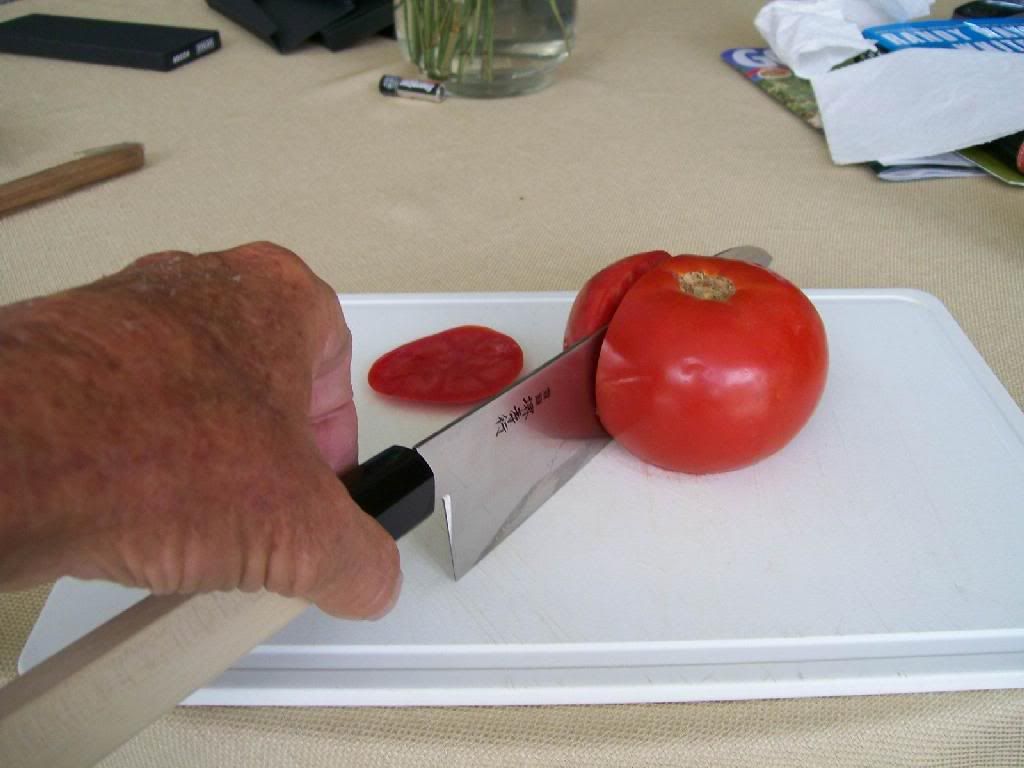

The result, as expected from this steel and geometry, was outstanding. It push cuts paper more than 2" from the pinch. I took a medium sized tomato, sliced the bottom to flatten it, and sliced it using nothing but the weight of the blade. Knife support was a light touch between thumb and fore finger to maintain a vertical orientation. One stroke forward, one half stroke back, DONE! Yowzer!

How it holds up remains to be seen. I like to chop.

This post is going up on a couple of knife specific sites tomorrow. Those guys know all the slang and shortcuts so I'll be adding additional information for NCT, all in blue. Sakai Takayuki is a Japanese manufacturer with a very wide range of knives, most are high end. The Grand Cheff series is in the middle somewhere. 240mm = 9.4" and that is the length of the cutting edge itself, from the heel to the tip. "wa" indicates a traditional Japanese handle as opposed to our familiar Western style handles. "Gyuto" literally means cow sword in Japanese. The reason I go into the detail I do is because I am the first to have obtained this particular knife. I placed my order 11-6-08 and it just arrived yesterday. The other folks know about it and they're waiting for my report. NCT gets it first.

I only have two other 240 Gyutos at this location for comparison, a 240 Yoshikane SKD and a 240 Aritsugu "A". Neither are very skinny but the pictures will show the relative dimensions. The spine is not eased like the Yoshi but is not nearly as sharp as the Aritsugu.

Edge: Out of the box and examined with a 20x loupe. The bevel apprears to be 50/50 and sharpened to about 2k.

"2k" refers to 2000 grit, the finest stone used by the maker to sharpen this knife.

Measurements are in millimeters.

Length:

Taka 240

Yoshie 248

Arit 236

Height at heel:

Taka 52 - lots of guys like knives a little on the wide side (I think me too)

Yoshi 47.6

Arit 44.5

Spine width above heel:

Taka 2.0

Yoshi 3.5

Arit 2.4

Thickness of blade at the heel half way between the spine and the edge:

Taka 1.0

Yoshie 2.3

Arit 1.4

Flexibility:

Taka Somewhat, but not too much

Yoshie Like a section of railroad track

Arit Slightly stiff as a knife like this should be

Fit and Finish is very nice. I already own a Grand Cheff 150mm Petty and knew what to expect.

"Petty" describes a Japanese kitchen utility knife.

The blade is solid SS AEB-L strip steel at RcH 58.

Swedish Uddeholm AEB-L is the twin sister of Sandvik 13C26. This is the steel from which nearly all safety razor blades are made. It is stainless, which is great for the home where the knife might be left wet on the counter or (shudder) in the sink for extended periods. This steel has very few impurities, and along with its tiny carbides that give it the ability to be made very sharp, is perfect for certain knife uses. "RcH 58" refers to how hard the steel is as measured by the Rockwell C Scale. As reference, German forged knives are in the 52-56 range and Japanese knives are generally 58-64. The scale is non-linear and means that 58 is much harder than 55. S.Sheperd can fully explain it if anyone cares.

I couldn't believe the edge. The bevel was hard to spot without magnification. To measure the angle I used an EdgePro Apex and a magic marker. It was a whopping 24 degrees per side, right up there with Wusthofs and the like. WTF? In its defense, it push cut computer paper quite well at 1/4" from the pinch. Magnified, the bevel widths were the same throughout the length of the blade.

More on push cutting on a follow up post.

Are you still with me? Wait till you see what this knife can do.

Geometry: The next two pictures tell the tale. The spine shot has the Yoshikane on the top and the Aritsugu on the bottom. The choil shot needs no explanation whatsoever.

Time to sharpen this sucker. Here's the stock bevel:

I'm a lefty and decided to sharpen the left side only - thank you so much Master KC Ma. LOL

Grit progression was:

Bester 700

Shapton Glass Stone 1k, 2k, 4k, 8k

Naniwa Super Stone 10k

Strop on leather .5 micron Chromium Oxide

Strop on leather .25 micron Hand American Diamond Spray

Here's the new left bevel at about 6-7 degrees:

The result, as expected from this steel and geometry, was outstanding. It push cuts paper more than 2" from the pinch. I took a medium sized tomato, sliced the bottom to flatten it, and sliced it using nothing but the weight of the blade. Knife support was a light touch between thumb and fore finger to maintain a vertical orientation. One stroke forward, one half stroke back, DONE! Yowzer!

How it holds up remains to be seen. I like to chop.

If you would sharpen my knives for me, I would be eternally grateful. I suspect I've never actually used a properly sharpened knife, even though I do use a steel every time I use a knife. Now, you need to figure out what I can do for you in return.

If you would sharpen my knives for me, I would be eternally grateful. I suspect I've never actually used a properly sharpened knife, even though I do use a steel every time I use a knife. Now, you need to figure out what I can do for you in return.

Sorry. Every time I look at your avatar I crack up.

Sorry. Every time I look at your avatar I crack up.